How many decisions can you concurrently manage? Our decision to purchase Hull Yeah, from the initial discussion to buy a boat, to closing, was about 3 months. That meant we had a ton of decisions to make, including insurance, what boat to buy, where to buy it, registration, taxes, loans, visas, and more. Depending on which boat we purchase, what systems are already aboard? Do we like those systems? Would we augment or replace them?

Looking back, the decisions were not quite cripling, but it was undoubtedly hard to prioritize and navigate them. Narrowing the decisions down a bit, this post focuses on the energy management decisions we’ve had to manage for our first season of owning a sailboat, and sailing Hull Yeah across the Mediterranean.

We’ve made significant progress on our Solar and Energy System updates since June of 2025. Many questions, decisions, and complications weighed on the current progress. While you might make individual decisions differently based on your sail plans, background, or comfort level, I hope this post helps you frame your choices and decide what’s best for your plans.

Where to Start

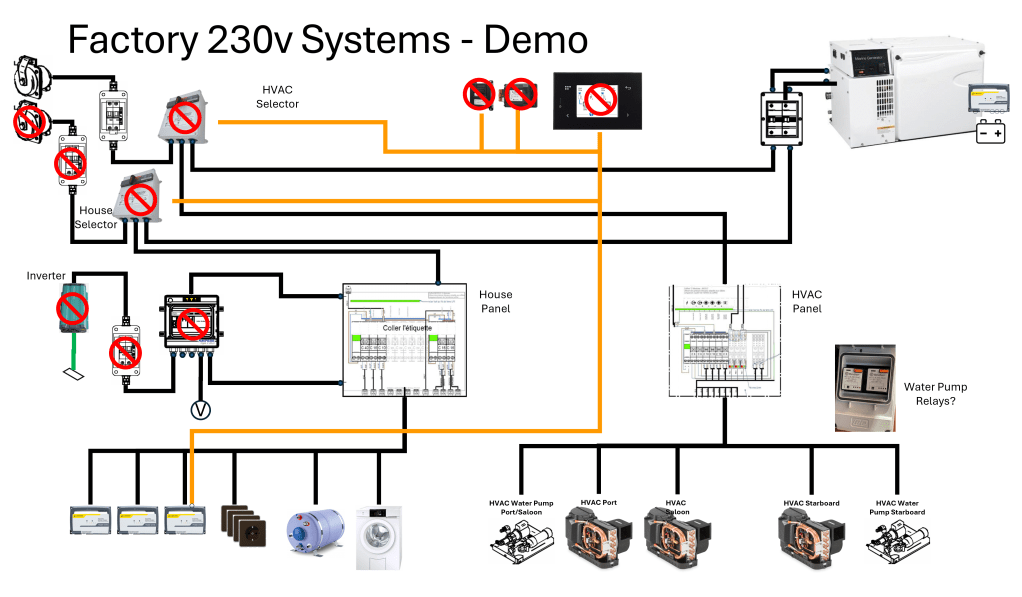

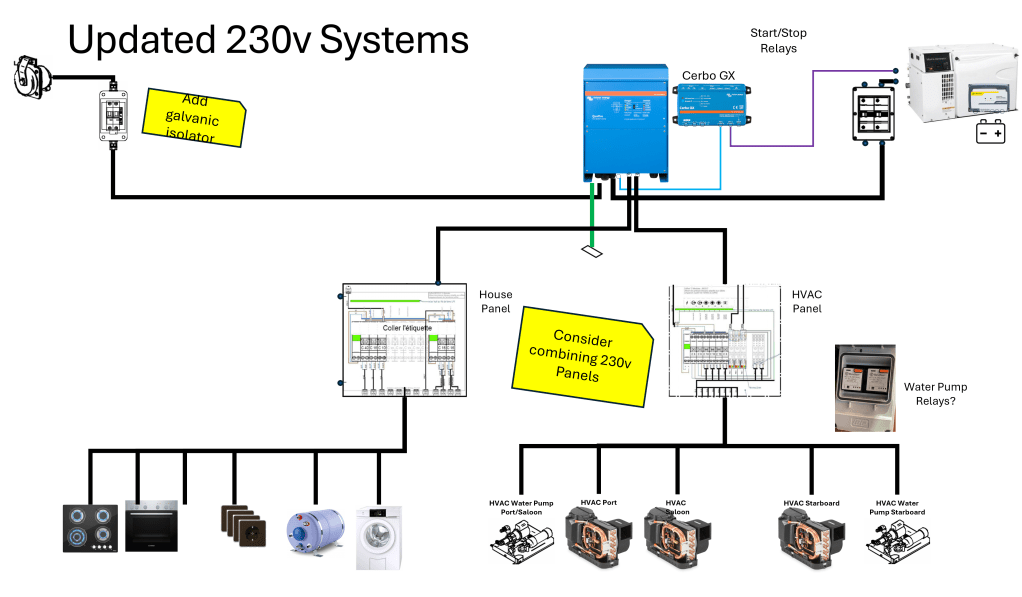

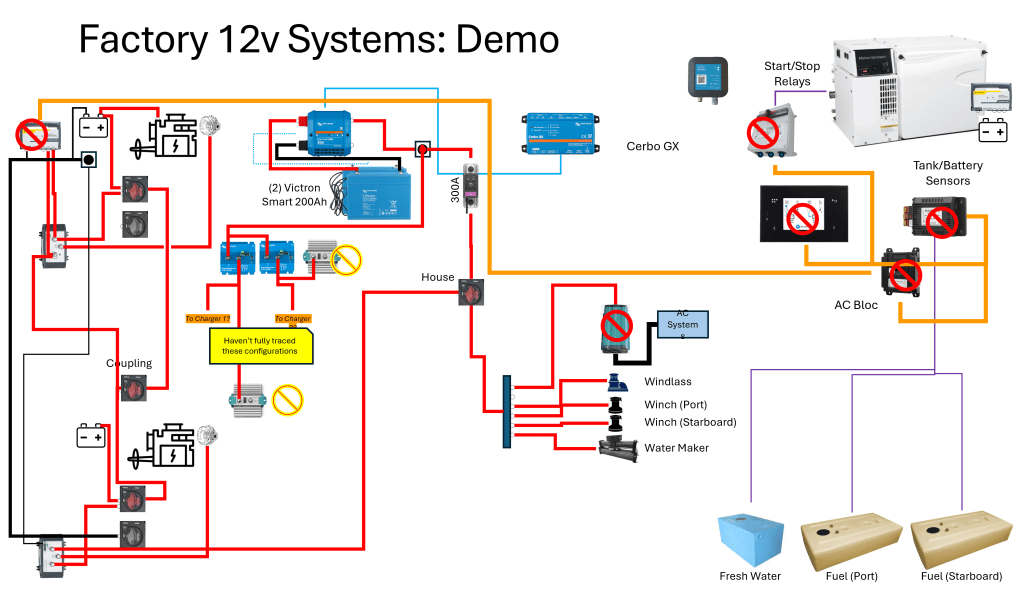

When we purchased our Excess 14, it had no additional updates from the factory-installed systems. It had 400Ah of factory-installed Victron Lithium batteries. This GenSet pre-install package included everything but the generator, a pre-install for a washing machine, gas appliances (stove/oven), and no solar. This was our best option, as energy systems are evolving quickly, and it allowed us to purchase the systems that made sense for our sailing plans. But it also meant we needed to make those decisions, including who would install them. Was it feasible to make the decisions, select the vendors, and complete the installation before our seasonal departure? We had grand plans and realistic expectations.

What are the Requirements

With so many choices, we needed to define our requirements for our sailing plans.

- Q: Are you day/week sailing, returning to a base port, where you have everything set up, from charging to a local chandlery you could order/deliver to?

- A: We will take off from Cyprus in May and return in November. There were no scheduled plans between.

- Q: How much time between marinas should you plan? Should you assume charging the batteries, filling the water tanks, doing laundry, and getting groceries in a weekly marina run?

- A: We wanted to be at anchor, over marinas, so we needed unlimited away time.

- Q: Are you planning long multi-week crossings, where redundancy is a critical component, as this can quickly get complex and expensive

- A: We would have a few overnight crossings, but no plans to cross the Atlantic. When/if we do, we’d add to, and not replace.

- Q: How much energy do you need to run the navigation systems, autopilot, winches, water maker, fridges/freezers?

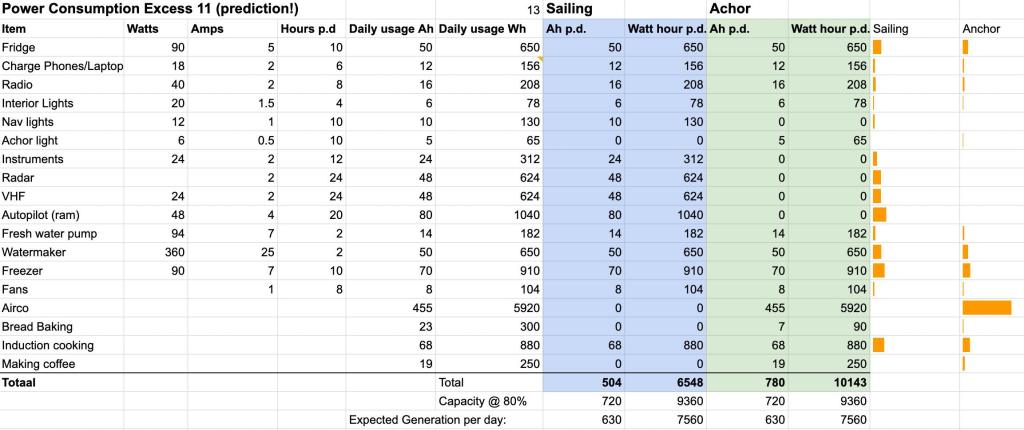

- A: Create a spreadsheet of consumption

- Q: Are you planning to cook with gas, and chase down refills, or cook with electricity, with the ability to regenerate as needed?

- A: We’ve learned that getting gas across the Mediterranean was a challenge. Some places would take a week or more to return a filled LPG bottle.

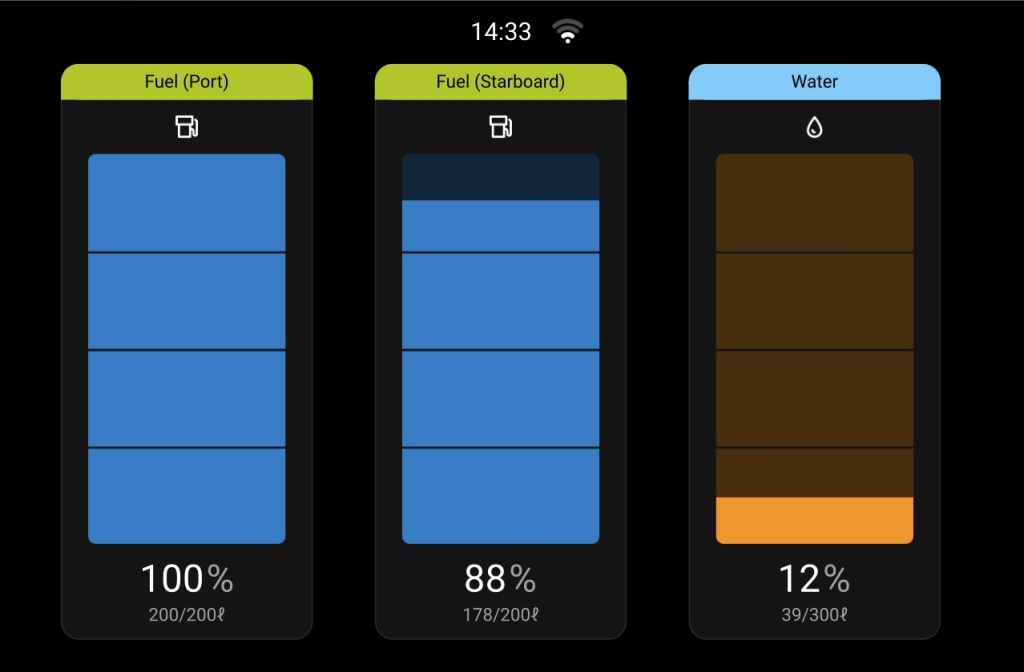

Our goals involved being off-grid, allowing us to stay at anchor. We would go to marinas, depending on the island, and the need for social connections, and unplanned repairs. Still, we wanted the option to sail as much as we wanted and to be at anchor as much as we wanted, without having to plan to enter a marina for charging or water.

This helps shape the questions about how much battery storage and solar we should get, and whether we should get a GenSet. Having more battery power was a factor, but it wasn’t simply about extending the time between marina charging. It was more about the buffer between charging. Could we run Air Conditioning in at least one hull overnight? How fast would the solar recover, or how long would we need to run a generator?

Complete Commissioning Before We Take Off

We had our general sail plans and completed energy consumption spreadsheets. We estimated how much each would need to be run, including how many times we might flush the electric toilet or run the winches. But we didn’t really know how much energy we’d actually use, or how much each system would recharge. There were so many questions we knew, and so many we didn’t know.

Some things we learned in hindsight:

- A 7kw generator will generate a lot of electricity to power cooking, laundry, the water maker, and air conditioning. But the charging rate of batteries is limited by the AC charging systems. The factory provided a 60-amp Cristec charger that was really slow, even for 400ah. It was a completely inadequate solution for the 1,200Ah of batteries we planned.

- 2,500W of solar is excellent, but limited by clouds and the shadow of the sails. We would occasionally tack or jibe just to optimize the mid-day sun, or choose different anchorages based on access to the sun.

- The intent and the reality of vendors’ ability to complete work on time were not the same.

- Finding components or getting deliveries was far more challenging than we had planned.

Along the way, I posted these as we worked through the choices:

As discussed in the Excess 14 Solar Upgrade Decisions post, we wanted Air Conditioning and electrical cooking. This meant we needed some more serious power available, and it wasn’t just a decision for how long the autopilot and navigation systems would run.

12v, 24v, 48v – Oh My…

As soon as we started discussing updating the power systems, the first question was, What voltage will we choose? Followed by passionate thoughts about why one would be “better than” the other. The reality is there’s no perfect choice, so we had to figure out what options were available to us.

Some parameters we considered:

- Excess boats come with 12V systems, including:

- Navigation Lights

- Refrigerators

- Alternators

- Interior Lights

- Bilge Pumps

- Water Maker

- Navigation System Electronics, including the autopilot

- Winches

- Windlass

- 24V and 48V systems would be more efficient and reduce cable sizes

- How easy would it be to get replacements as we depart in March, return in November, and don’t have a “port of call” in between? There’s no run to the local store on the weekend.

There are many more things to consider, but those capture the big categories.

24v or 48v

The first decision is whether to deviate from the factory-provided 12V system. If we do switch from 12v, would we choose 24v or 48v?

Many of the systems aboard Excess boats support both 12v and 24v by simply changing the voltage, including the refrigerators, which didn’t even require a switch. In fact, the double fridge/freezer supports 220V, in addition to 12V/24V. Many navigation systems also support 12V/24V. Raising the voltage would make the existing wiring more efficient. However, none of those systems would support 48V. Choosing 48V would either mean we need to swap out many components, step down the voltage at the components, or manage 12V and 48V systems.

Starting Point

There’s no question that 24v or 48v systems are more efficient, but what’s the starting point to that efficiency? If we were building a new boat with all new systems, we’d most likely go with 48V systems. We could provision all, or most, of the electronics with 48V. We could reduce the wiring sizes, lowering the boat’s cost and weight.

However, as the boat was already commissioned with 12v, most of the heavy, expensive cables were in place, and all components were installed. This really discounted the “value” of switching.

Multiple DC Systems

Since we couldn’t justify switching the entire boat to 24v or 48v, what about having multiple systems?

Loads are broken down into two major categories:

- DC Systems for navigation, winches, windlass, and lighting

- AC Systems for cooking, heating/cooling

What would it look like if we broke the DC systems into two subsystems?

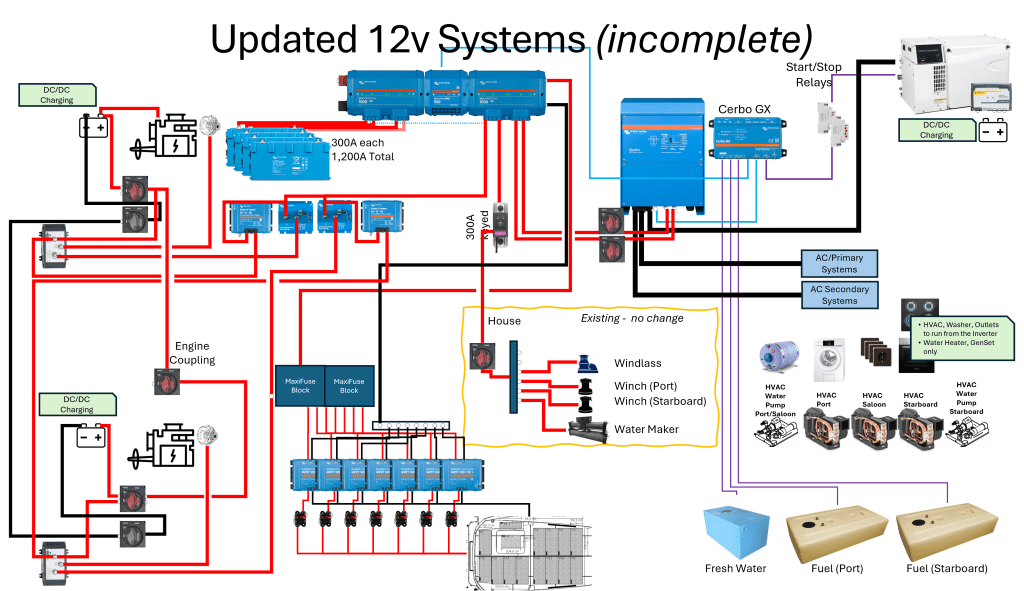

We already have 400Ah (2 x 200Ah Victron LifePO) batteries on board, along with all the chargers and subsystems. Why not keep that and add a 48V system for the inverters?

When doing the math, we could definitely benefit from 48V batteries to feed the inverter(s). This would increase the time we can live on fully charged batteries. But, how do we charge the batteries? This means 48V solar systems and 48V chargers from the dock/generator. I’ve seen articles where owners separate their solar panels into 12V and (24V or 48V) charging series. On the roof of a house, where there’s lots of room, and all panels are essentially equal in their capacity to capture the sun, splitting panels would make sense.

On a boat, even a large-ish catamaran, we’re constantly fighting for every angle of the sun. We choose anchorages and debate if tacking or gybing would yield better solar capture. If we could use the same solar panels and MPPTs, or if another distribution system could split a common solar output across a 12V and 24/48V system, I could see that working.

KISS a 12V System

When considering the options, these were our final factors, and why I chose to Keep It Silly Simple (KISS), and stay with the factory baseline of a 12V system:

- Splitting the solar into yet another subset of 12V and 24V/48V was more complex than I wanted

- Space for additional electronics wasn’t a concern, but adding more complexity to the system was. Complexity is the alternative to reliability.

- Rather than have multiple systems (12V and 24V/48V), I’d rather invest in redundant systems. For instance, two smaller 12V / 3KW Quatro inverter/chargers.

- The Excess line prides itself on weight reduction. While electronics don’t add much weight, it was a minor justification.

Baseline Charging

When power companies plan how to manage their capacity, they consider baseline and peak loads. Nuclear is a typical baseline system as it can run for months without interruption, is complex to start and stop, and isn’t impacted by wind or the sun. Hydro is simple to start/stop, if there’s enough “head pressure”, providing another great baseline. Gas-powered plants are easy to turn on instantly to meet peak loads and boil tea at halftime of the football game. They’re not as efficient or cost-effective as hydro or nuclear power, but they’re great for peak/fill-in service.

On a boat, what are your baseline energy providers, and how do you supplement them as the peak loads kick in? Our batteries are our baseline power providers, but we need to recharge them. Since we don’t plan to use marinas for most of the season, we can’t depend on plugging in at a marina. We needed a solution that wasn’t simply extending our stay by a few days between shore-power recharging. That means we need to recharge the batteries with some combination of a generator, solar, and/or high-capacity alternators.

Can we layer these as incremental improvements?

There are many decisions to make between generators and high-capacity alternators. While there are many choices for solar, adding solar in the Mediterranean is a no-brainer. There’s plenty of sun, and the days are long. This actually simplified things a lot, as we could focus on solar as our baseline charging, with everything else filling gaps. I’ll dig into the solar decisions a bit later and how much we felt we could reasonably add, which will impact how we supplement recharging. In either case, we knew we wanted/needed the option to run air conditioning overnight. We’re sailing for enjoyment, and sweating through the night wasn’t going to be enjoyment. How often that would happen was a question, but we knew it would be needed enough to account for it.

GenSet or High-Capacity Alternators

Knowing our base charging will be solar, we needed to consider how much regenerative power we would need, how often that would be required, and what that pattern might look like.

Some things to consider:

- The engines are designed to provide propulsion, which can also provide power take-off for charging. They are not optimized to run as a charger without a propulsion load.

- It’s nice to have dual-purpose engine output while anchoring/docking, as we could charge while maneuvering; however, it wouldn’t solve the auto-start/stop needs when the batteries run low.

- While we knew we’d run the engines for anchoring/docking, we didn’t plan to run them much, as we planned to sail the majority of the time, and that held true during our 2025 season.

- A generator is designed to provide AC power consistently and for long periods.

- Alternators provide DC power to charge batteries and power inverters, but can’t run AC systems directly.

- A generator provides AC power, which can also power high loads such as cooking, water heating, and air conditioning, as well as charging batteries.

- A generator can be run at any time.

- With the Victron Cerbo GX, it can automatically start/stop during the night, assuring we’d have overnight cooling.

- A generator is far quieter than running the engines

The high-capacity alternator options are another rabbit hole. Some of the challenges included:

- Impact on the Yanmar Warranty

- Cost of the alternator system, and the cost of the Yanmar-approved bracket

- Complexity is added to the system as you have multiple charging sources

- We saw overcharging alarms as the stock alternators were charging, while the generator was on, charging through the factory-provided Cristec chargers

- I saw a similar issue happen with a hydro system running while the engine and solar were running

- These can likely be managed, but it’s an additional complexity to consider

- How much would we run the engines, as we sailed the majority of the time

- The exception was anchoring/docking, which does run the engines for about 15-30 minutes, and could benefit from high-capacity alternators

- How much do we want to run the engines for just charging, increasing the usage beyond powering the boat

- Which high-capacity alternator system should I choose that wouldn’t affect the Yanmar or Excess warranty?

- Do we put it on both engines, or just one?

For all the questions above, we ultimately decided to defer the decision on the high-capacity alternator until after we sailed a season. I didn’t feel it would solve our need for peak AC loads like cooking and air conditioning, navigating the Yanmar warranty issues, and the costs didn’t line up with the questions above.

Atlantic Crossing Insight

At the end of the 2025 season, I had the opportunity to sail across the Atlantic on another Excess 14. They had 4,000W of solar across the roof and davits, 1,200Ah of 12V batteries, and all-electric cooking. They didn’t have a generator or high-capacity alternators, but they did have a hydro-regenerative system.

By the end of the first day, we were already in trouble. Apparently, we left the docks with 40-60% of the batteries and were struggling to catch up. I was surprised and disappointed that the 4,000W of solar wasn’t generating as much as I had assumed. Partly because there was some haziness, and partly because the sails were covering the roof and even the davit-mounted solar panels. I was disappointed as I was installing 2,500W on Hull Yeah, and I thought that was already overkill.

The hydro system triggered an overcharging alarm, and they had previous problems that weren’t worth adding to the risk of our crossing. The hydro system went unused, adding to our drag without adding to our charging capacity.

We ran the engines at about 1,200 RPM, which maxed out the charging capacity without running them too hard or consuming too much fuel. However, it took a long time to charge the 1,200Ah-capacity batteries, and we ultimately used so much fuel that it raised concerns about our overall consumption.

It was a great example of believing there was more than enough capacity, myself included, but in practice, it wasn’t enough, with limited options for recharging.

Adding a Generator

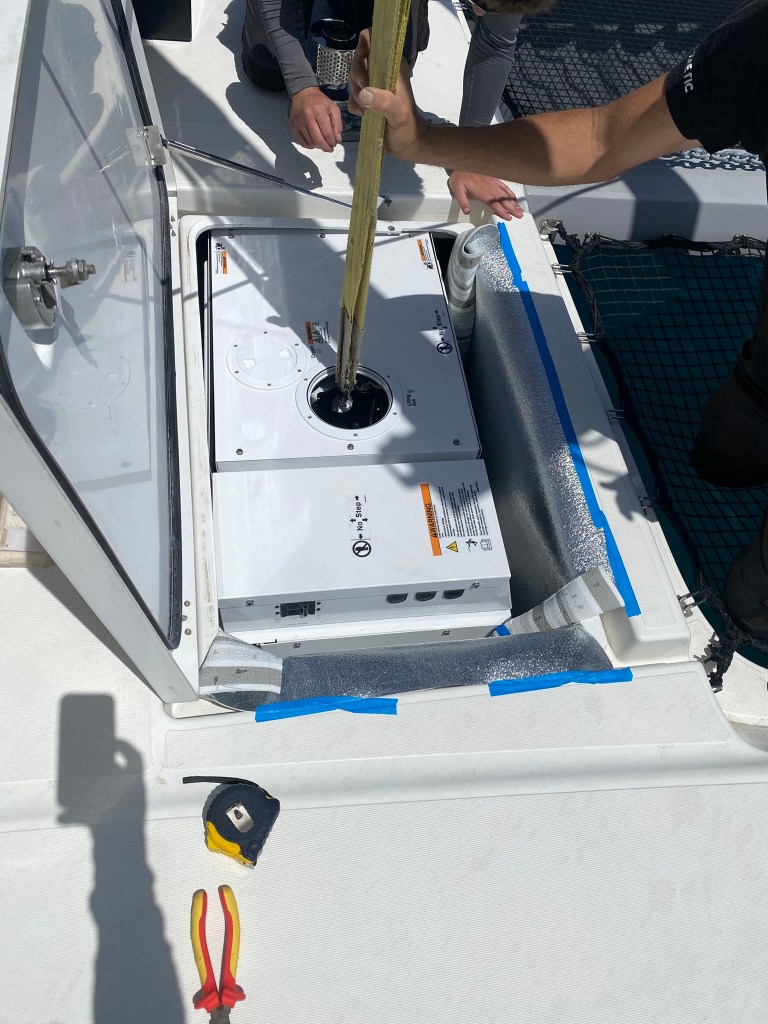

The boat was built during COVID, when generator supply was limited due to supply chain issues. It was commissioned with the factory-provided GenSet pre-install. It’s an €11k option that includes electrical wiring, fuel lines, switching between port/starboard fuel tanks, a fuel lifting pump, through-hulls, a cooling pump, sound insulation in the locker, a battery and charger, and a platform to secure the generator. All we needed to do was simply lower a generator into the locker and connect everything that was sitting there.

In hindsight, even if I had to commission all the pre-installed things, I’d still go with the generator to have the peace of mind of a dedicated generator that would be there when we needed it. Yes, it adds weight, yes, we want to go fast, but I’d make the choice again, based on the systems available today. And we’d still have engines with low-capacity alternators as backup.

What We Did Before, During, and After the Season

It’s now January 2026. I have the benefit of hindsight to evaluate what we intended, expected, and ultimately what happened. As the saying goes, “2020 hindsight“, and “I wish I had known then what I know now.“

The Plan

We started the purchase at the end of March 2025. The owners and the broker allowed me to live aboard, even though we didn’t actually complete the closing until late April. This time, provide us time to plan, but we couldn’t actually start tearing things apart until ownership was transferred. Once we took ownership, we had a window to complete the updates before we left for the season.

My son got married at the end of May, which meant we flew back to Seattle, and we’d return to depart the first week of June. It was already late in the season, so we didn’t want to add any more delays. This gave us May to complete the updates.

We had every intention of installing the GenSet, batteries, charging, and solar before departing Cyprus the first week of June. We engaged in all the discussions above, which took more time to research and decide than I had expected. It seemed every answer to a question was met with more questions that required more research. The choice of Solar Panel vendors and how they were installed was a big decision.

The vendor had grand plans to complete the work, but “life happens”: the owner had a medical emergency, making it unrealistic to finish.

The Reality

Triaging the priority list, knowing solar could be deferred, and all the other systems had too many questions, I opted to install the GenSet and make that our baseline. We knew 400Ah would last a day of sailing, and the GenSet would fill any gaps until we had more efficient systems installed.

We left Cyprus on June 6th, as planned, and continued to research on a less stressful timeline. I gained more insight into our actual usage, including how little we used the AC when at anchor, but we used it enough that I’m thankful we have it, and the GenSet to power without worry. I was able to ask other sailors about their experience, applying the filter of their style compared to ours. Some folks didn’t mind the heat or were more cost-constrained.

Roof and/or Davit Mounted Solar

The first decision was how much solar to install on the davits and on the coach roof. Davit-mounted solar panels are cheaper and far more efficient because they are solid panels with cooling underneath. Compared to flexible roof panels, which are more expensive, less efficient because there’s no undercooling, and have the added complexity of removal/reinstallation when they fail.

We currently have the original davits, which sit lower and can be affected by waves from behind. We may switch to the new davits, and we are still in discussion with Excess. We also really like the view to the rear, which is our typical place to enjoy our surroundings at anchor and sailing.

Putting davit-mounted solar panels would interfere with the view. Enjoying the fantastic view has a “value”.

The other challenge was our choice of dinghy. As we view our dinghy as our car, we wanted something comfortable and easy to drive, so we opted for a console/seat setup. This means our dinghy has a higher console and steering wheel profile, raising the height of potential solar panels.

Given the dinghy profile and view, and the possibility of replacing the davits, we opted to install only coach roof-mounted panels. We could always add davit-mounted panels in the future.

Top Mount or Undermount Wiring

With the decision to do roof-mounted panels, the next decision was how to run the wiring. All the other Excess boats we viewed, and all the vendors we met with, were running the wiring above the roof. They used various approaches to run wires through stainless conduits. All were very clean and impressive for their quality of work and craftsmanship.

One of the things I loved about the Excess line was how easy it was to manage the mainsail. The majority of our time would be spent short-handed sailing. It was so simple to step up onto the roof and look down into the sailbag, which makes raising and flaking an expensive sail super easy. It was also safe in +30kt winds to douse, reef, adjust the leech tension, or close the sail bag.

There was no concern about tripping when bouncing around, and no fear of loose reef lines catching on the wiring. During a previous charter, we found the roof-mounted solar panels on an Elba 45 had been torn off. Apparently, the slack reef lines caught the little pigtail from the panel, damaging 3 panels. The panels were mounted behind the roof seating, making it hard to see. Not only was this expensive to repair, but it also adds to the complexity of managing the sails.

At the Miami Boat Show, I saw the new HH and Windelo boats, as well as several others with clean, undermounted solar panels on their roofs and some on the hull deck. I was committed to pursuing this clean design.

Is this going to be easy? Hell no, but it’s a boat, and there’s no expectation of being easy. It’s a matter of whether it’s possible, and how much “pain” it will cause. Either financial pain to pay someone to pull off the magic, or personal pain to figure it out myself. “No pain, no gain”, so next was how to achieve this obsessive plan.

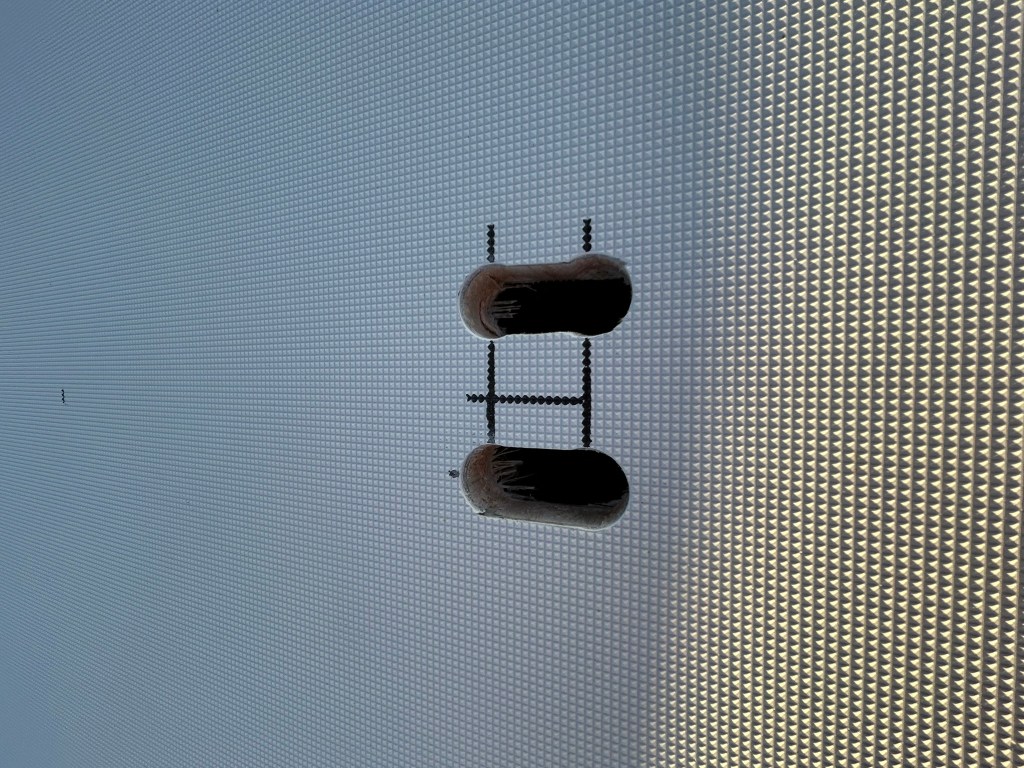

Undermount Wiring and Endoscope Cameras

The Excess 14 roof has two sections. The area over the saloon has a removable cloth headliner. And the cockpit with channels that might support hidden wires.

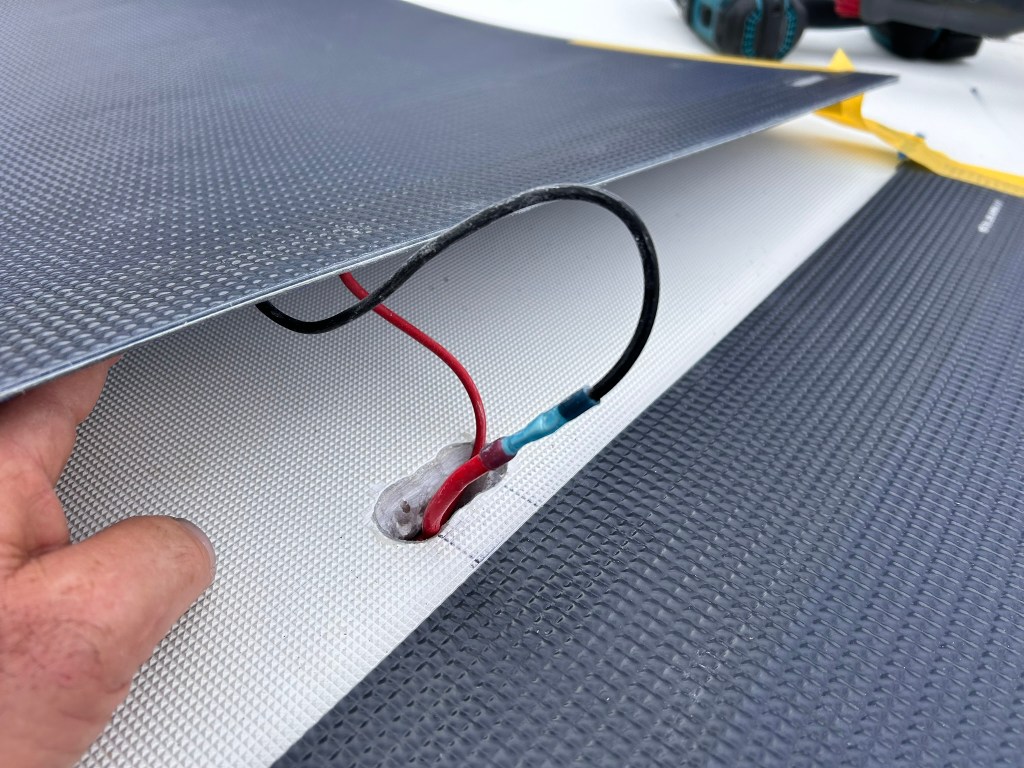

Thanks to this handy dandy endoscope camera, I was able to run it through the salon ceiling lights to view the open space. And confirmed the structural support channels of the cockpit roof were all connected. Drilling a small hole between the salon and cockpit, I could run wiring from the salon into the channels, even making the turns. Ahh, I can achieve the perfectly clean rooftop I had hoped for.

The wires could be run from the roof, down the interior port side of the sliding door, into the port hull. It would require a slight modification to the cosmetic covering of the existing wiring that runs down the interior port side of the door, but it would be far less impactful than all other options.

Solar Panel Vendor Choices

It turns out there were lots of panels with top-mounted wiring in various sizes, but very few with under-mounted wiring. The search switched from expensive, flexible stock sizes to even more costly custom panels. As a result, I had to revisit my plans for undermounted panels.

When faced with these types of decisions, I apply two filters. Can I make a largely additive change later, and what part of the decision will I remember and regret most? Assuming the project can incur the costs, and this is a very real part of the decision, I’ve found that spending more money up-front is something that I forget over time. However, continually staring at the decision to save money vs. have an improved experience becomes a nagging thing I constantly wish I had made a different decision. Over time, I can forget the money spent and have a story to tell about the complexity of implementing a better experience. It’s the experience that has the most significant impact on our usage, and will also help the resale of the property, or boat, in this case.

Being confident in my commitment to the cleaner and safer undermount panels, there were a few leading vendors I was considering at the time:

- Canadian-based Open Waters Solar

- Italy-based Solbian SP Textured Black Panels

- SUNBEAMsystem Tough+ Black Solar panels

- Phaesun Mare Flex 155

There were other cheaper brands, like OffGrid, that didn’t hold up over time. Installing affordable, bolt-on panels to the davits was one thing. Gluing down panels to the roof was an entirely different effort. I saw a few articles where owners spent ~100k to remove the panels and repair the roof. Installation and removal were new parameters I added to my evaluation process.

I met the owner of Open Waters Solar at the Seattle Boat Show, and they impressed me with their commitment and durability. They installed helipad-mounted panels on a boat, demonstrating their durability. They were a new startup, but I was impressed and ready to move forward. The costs and delivery time to Cyprus had me look at alternatives. I would strongly consider them for a future project.

If I remember correctly, SUNBEAMsystem and Phaseum didn’t actually have undermount wiring or custom panels. This might have changed, and I don’t remember.

When researching various brands, Solbian kept coming up as a top reliable brand, and the panels used on several of the high-end boats I saw at the Miami boat show. They had an Excess 11 case study that I thought would be carried over to our Excess 14 design. The challenge with Solbian was getting in contact with them.

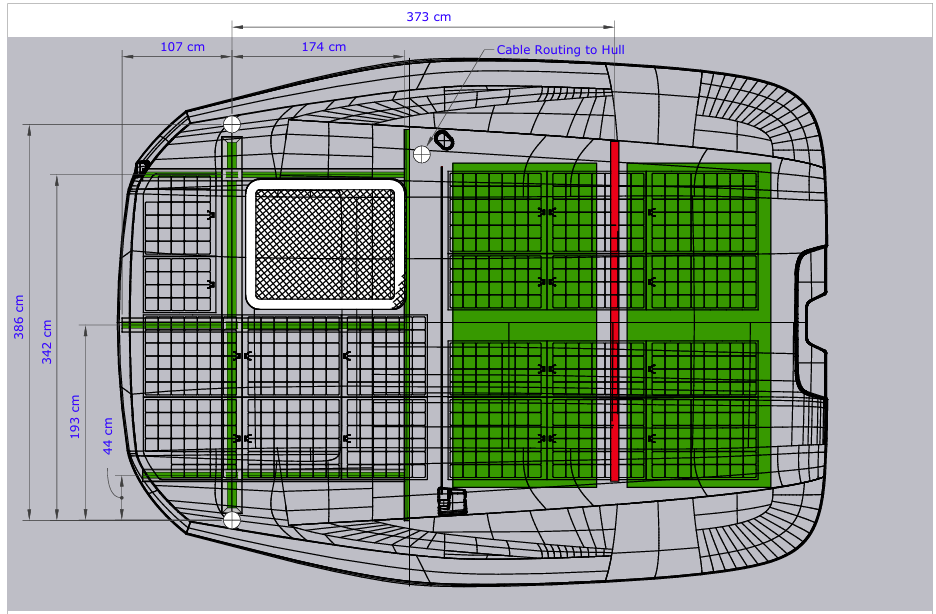

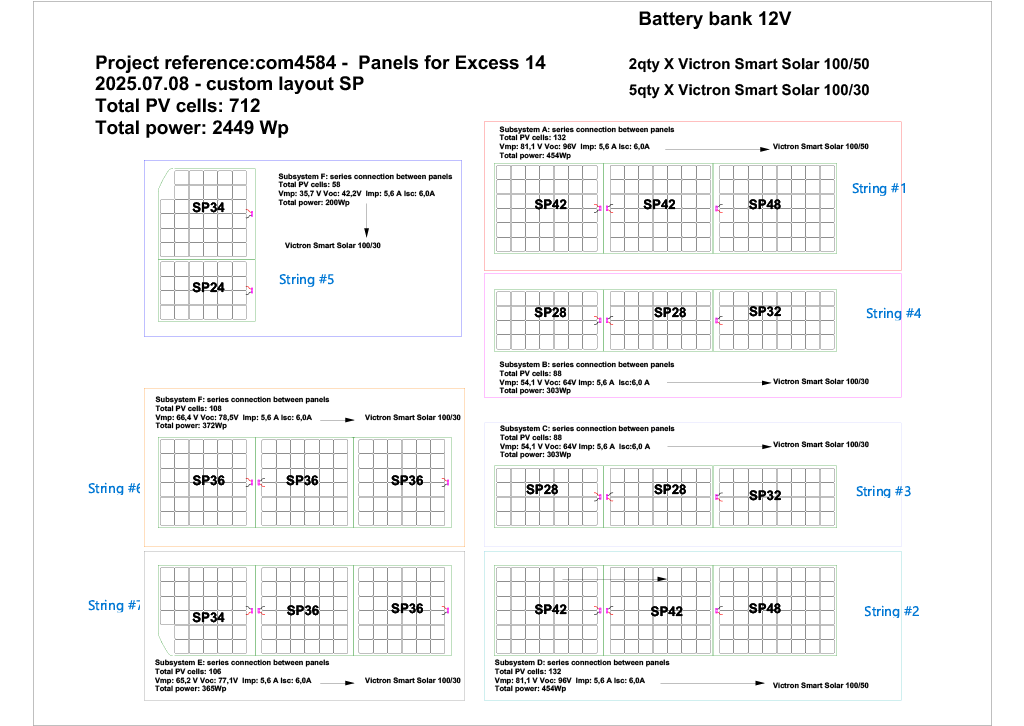

Once engaged, their design department was fantastic. They had a 3D model of the roof from a previous bid. They didn’t finish the install, so I had to provide the channel measurements, which indicated where the wiring would be attached to the panels. Hull Yeah has the rooftop seating, which I call the hottub. We discussed maxing out the capacity and the level of flexibility the panels could support.

In the diagram above, the green areas represent where cables could be run. The cockpit areas reflect the supportive V channels. The green areas in the salon represent the open space, while the red channel is a support area I neither wanted nor needed to access.

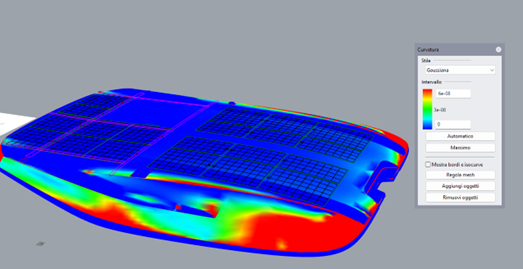

To confirm that the panels would flex and adhere to the roof, they applied the design in a 3D modeling program, indicating the safe areas for installing the panels.

Decision Criteria

Ultimately, I decided on Solbian for the following reasons:

- High-quality product, with installation on several high-end boats

- Great support, once I got connected with the factory in Italy

- Excellent custom design that met our needs, including aligning with the channels in the Excess roof

- Detailed analysis for creating 7 strings, aligning with our needs of a 12V, 1,200Ah battery bank

- Adhesive backing that didn’t require glue. This was a cleaner install, allowing non-destructive removal when needed. No concerns of a 100k removal/repair.

You’ll notice I didn’t include the price and the decision criteria. The 20 panels, black caulk for the edges, 7 Victron MPPTs, 7 breakers, and 170m of red and black wires to extend the panels to the port/aft bed were close to €20,000. There was another ~12,000€ in Victron equipment to complete the install, including the Quatro 5kW inverter, 4x300Ah LifePO batteries, 4/0 and 3/0 distributors, Smart BMS, and cables for the batteries and the inverter.

Finalizing the Overall Design

With so many decisions, the complexity, and the decision to complete the work myself, I knew enough to seek professional guidance. Living in Seattle, WA, I was familiar with Pacific Yacht Systems, including many online videos and seminars. I would have loved to have them do the install, but traveling to Cyprus, or somewhere along the way, wasn’t practical. The next best thing was to hire them for consultation. This was money well spent. It confirmed things I believed, added new information I hadn’t considered, and helped me finalize the design.

As prep, I documented what we had aboard, what we’d remove, and what we’d install.

The complete PowerPoint, with all our decision criteria, is here:

One of the additions from meeting with PYS, not yet incorporated above, is the addition of DC/DC chargers for the 2 engine batteries and the generator. This is part of the spring 2026 updates.

Deliveries on the Greek Islands

This turned out to be more of a challenge than we had planned. We took off in June, and we finalized our decision to go with Solbian and the final panel layout in early July. Solbian had a 2-week lead time and was closed in the month of August.

We arranged to have the panels delivered to the Kalamata Marina. This part worked out well. Unfortunately, the Victron order was delayed, arriving two weeks after we had left Kalamata and were navigating back up to Athens. It took several more weeks before we could arrange to have the batteries, inverter, and other supporting gear delivered.

We learned that deliveries on the Greek islands align with the islanders’ relaxed culture. The term Siga Siga (pronounced “see-gah, see-gah”) translates to “slowly, slowly”. Deliveries would arrive in Athens quickly, then sit for several days, sometimes longer. All the shipping companies have the same problem. They contract with local shipping companies to navigate the ferry systems. And they arrive when they arrive. Due to the delays, the panels sat in the forward berth for several weeks before the remaining Victron gear arrived.

The lesson learned is to assume deliveries will take weeks longer than promised. If you need something fast, ship it with the next crew member that will be joining you, or to the mainland, then either sail to the mainland or take a ferry. What we like about the Greek culture is its relaxed style. This applies to all the businesses that operate across Greece as well.

Installing Solbian Solar Panels

It’s mid-September before we finally start the install, but we have a well-thought-out plan to execute.

Drilling the holes in the roof was a big commitment. The roof is balsa core fiberglass. You must assume water will work its way under the panels and into the holes, which could reach the balsa core. It’s a problem to have a leak, and you need to remove the headliner to re-seal the holes. It’s a far worse problem to tear apart the roof to repair a soaked balsa core. This meant we needed to drill the holes larger than necessary, carve out the balsa, and fill the perimeter with fiberglass-impregnated resin. The approach I took was to drill holes through both layers of fiberglass, then push thickened, fiberglass-reinforced resin into them. We’d then re-drill the holes for the panels.

2020 Hindsight Tip:

In hindsight, I should have drilled through the top layer and the balsa, leaving the bottom layer. Then pour thickened/reinforced resin into the holes, without it falling through the bottom into the cavity. Then, drill the final holes all the way through.

Once all the holes were drilled, we ran the cables, creating 7 different series of panels. Solbian did all the calculations, optimizing each string for sail shadowing and for proper charging voltages. While the MPPTs regulate the voltages, they must have a voltage greater than the batteries they’re charging.

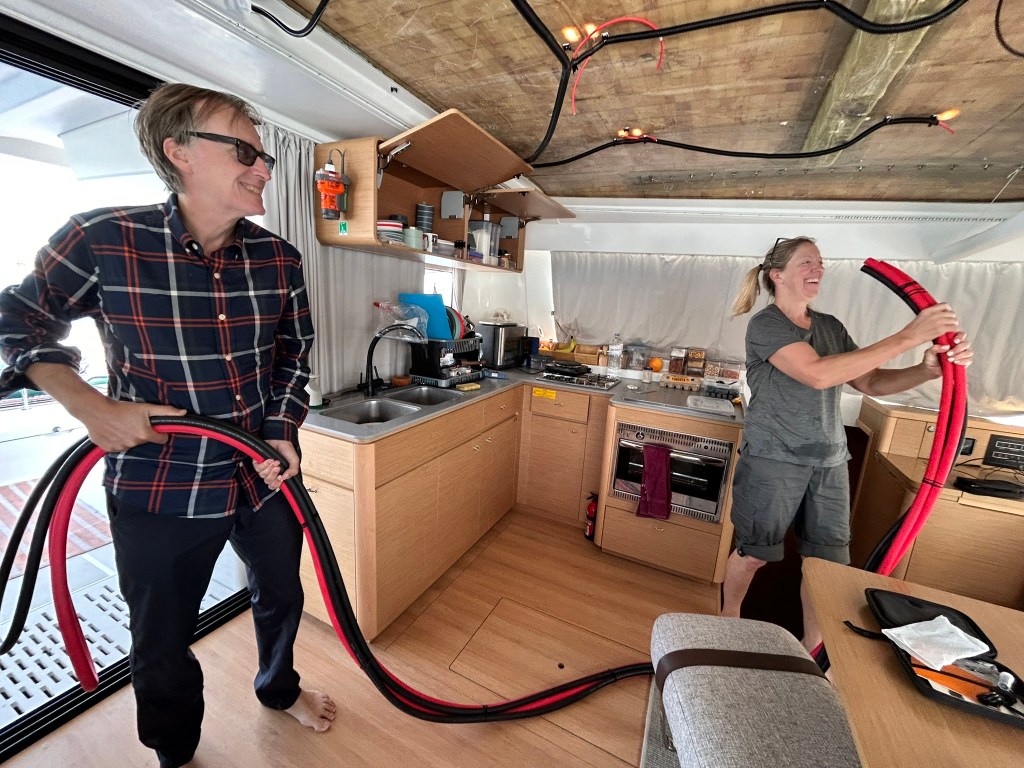

Running the wiring involves 7 pairs of wires, from the roof down the kitchen wall, through the cabinets, into the hull, back into the area below the bed.

While Excess installed the 400Ah batteries and support gear in the port engine compartment, we opted to relocate them to the environmentally protected hull.

To create the series of panels, jumpers were needed between the panels. Fishing the cables between the holes and around the bends was a tedious task. The endoscope camera, a stiff but flexible wire, some hangers bent into hooks, and a lot of patience were the tools. With the wiring completed, we could install the panels per the Solbian procedure.

Another tip is to heed the warning and fill the gaps in the deck traction. That 1cm groove will provide just enough give that could damage the panels.

With some tape, the edge of a wooden spoon to shape the caulking, and a sunny day, we completed the caulking.

MPPTs, Breakers, and Distribution

With the wiring in the hull, we were finally ready to convert solar power into our batteries. The 7 strings of panels are connected to breakers that feed the MPPTs. The MPPTs then go through a set of fuses into the distribution panel. I’ll upgrade the bus bar in the spring, as supplies were limited. We ran (4) 4/0 cables (2 black, 2 red) from the Victron distribution to the port electrical cabinet. Wrestling “the Anaconda “was left to Jacki and John, who were so helpful this season, joining us 3 different times.

Batteries And the Inverter

The space at the bottom of the above picture will store (4) 300Ah Victron Smart Lithium batteries, which will get connected to the left Victron distributor.

We were still hoping between islands, and were close to the end of our season. Rather than dismantle the existing batteries, shunts, battery protect, fusing, and BMS, I opted to connect the solar to our existing battery system. Once we returned to Cyprus, we only had 10 days to wrap up the boat for the winter and depart for another boat to cross the Atlantic.

I’ll take the time in the spring to complete the conversion.

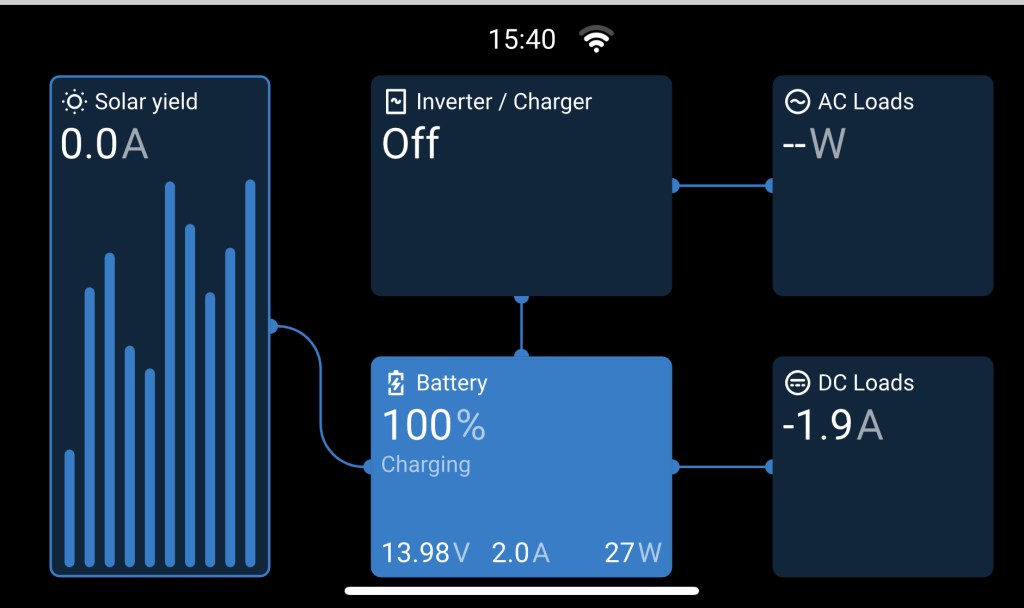

Converting from the Scheiber system to Victron

The more I learned about the Victron system, the more impressed I was with the features and usability. Not only does the Victron Cerbo GX incorporate all the battery, solar charging, and inverter monitoring, but it also provides automatic GenSet management. I have another article coming on how we’re switching out the Scheiber system, so stay tuned.

Winter Recess

That wraps up the updates for the 2025 season. If you’ve gotten this far, thank you for reading. It was far more complex and took far longer than we had planned. This article skipped much of the noise we encountered along the way. I hope this helps frame your decisions, and I hope I surfaced a few things you may not have considered. It’s not really about reaching the same conclusion we reached. It’s about figuring out how your plans and answers to the questions meet your needs.

Were there other parameters you considered? Please let me know if this was helpful and if you have any other feedback.

Steve

Leave a comment