Excess 14 Sail Rigging Modifications

These are modifications we’ve made while sailing in the Mediterranean. They may, or may not apply to other regions or crossing, and this is just our experience as a first year owner of a catamaran.

Foresails / Bowsprit

Since getting our North Sails G0 and G2, we’ve used the bowsprit quite a bit. There are 3 elements that led to changes:

- Our Code 0 (G0) has a Facnor endless furler. If the tack isn’t pulled tight, the combination of the space in the tack lines enables the furling lines to work over the top of the furler, twisting the entire furler, ruining a douse. Pulling the tack tight is required for the torsion rod, but we didn’t expect the furler to twist on the spare tack line.

- The Gennaker (G2) has a sock that requires the tack to be loose, removing the power from the sail to pull the sock down.

- When sailing deep downwind (~140-180), releasing the tack puts more curve in the sail, raising it higher and projecting further forward. Which of course needs to be pulled back in for 110°-90°.

The stock setup on the Excess 14 has a friction “thing” at the bowsprit. It also has a Dyneema chaffing protector, which adds some slippyness to pulling it through the friction block. It has a short line, with a clutch on the base of the bowsprit. However, even with the 2:1 leverage, any load makes it’s impossible to pull in, or even release.

To solve this, we made two changes:

- Add a block, enhancing the Antal friction “thing”

- Extend the tack line back to the starboard helm piano, enabling use of the winch to pull it back in, or release with subtle control.

These two relatively minor changes have made a huge difference as we can actively trim the tack for the Code 0 or Gennaker for raising, dousing or downwind.

Additional Bow Tack Points

When sailing deeper angles, the center point of the boat isn’t the optimal location. With the advice of Avi from Easy Sails, we added two Antal T-Locks with friction rings. (youtube) These are sexy mounts that are flush when not used and quickly added when we need them. This required holes and some reinforcing of the bow from underneath to add strenght, and provide the thickness for the nut. We opted to epoxy them in place for additional strength and avoid any leaking.

[note to replace with the tack on the T-Lock]

I know I just discussed the block for the tack, and now I’m using friction rings on the bows. While we do shift the entire load to each bow, we haven’t seen binding like we do on the original friction “thing”. The low friction rings are rounded and haven’t been an issue.

When rigging our downwind sails, we add two additional lines, connected to the tack, and run back to the starboard helm piano. With these lines we can pull the tack to either side, projecting the Asym sail directly in front of the boat. While not intentional, I’ve seen it go 165 on the opposite tack and just start to flutter. We don’t yet have a reaching symmetrical sail, but these would benefit from the T-Locks as well.

Why No Bow Cleats

We opted to not use bow cleats, which could double as mooring cleats as we didn’t want to risk things to snag sheets. We haven’t used any mooring balls in the med as they’re generally not trusted to be maintained. We’ve heard other options, including using the bridal, or rear cleats that make it easy to back up to the mooring ball and grab it so the T-Locks have been an awesome way to balance simplicity, usage and avoid problems with snagged lines.

Dreaded Twists

The other thing to keep in mind is the dreaded twists of 2:1 halyards. Using the winch under load, such as raising the halyard, can send clockwise twists into your lines. These twists will work their way up the halyard to the 2:1 anchor point at the top of the mast. What makes this dangerous is the twist can bind when dousing, The combination of the twist and a UV damaged halyard, can cause so much friction the sail won’t come down. This happened once, and we had to sail 20 miles to an anchorage, then climb the mast to remove the twist to lower the sail. This falls in the “never again” category, along with salt water toilets…

To solve the twist, each time we raise, we roll the halyard counterclockwise in our fingers when coiling. If you watch the pattern on the halyard, watch if it’s sending twist up the mast when dousing. If you see the twist, STOP and remove it before sending the twist up. While it’s a complete PITA (Pain In The Ass) to do each time, it doesn’t take more than one long sail with the expensive sail floundering on the mast to do each time.

Occasionally you may have to remove the halyard to remove the twist that’s made its way up to the top of the mast, at the anchor point. This applies to the Main halyard, main sheet as well, jib sheets, jib furler or any of the lines you put on the winch. The jib halyard isn’t typically a problem as you we don’t raise lower it more than 1-2 times a year for inspection.

Mainsail Changes

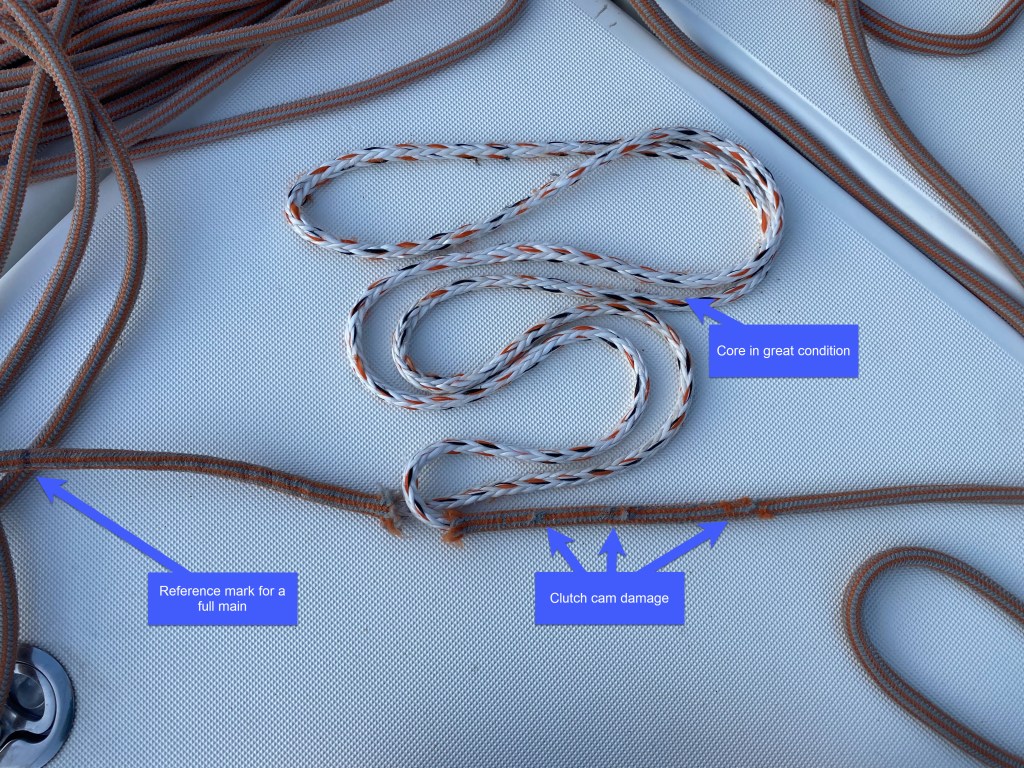

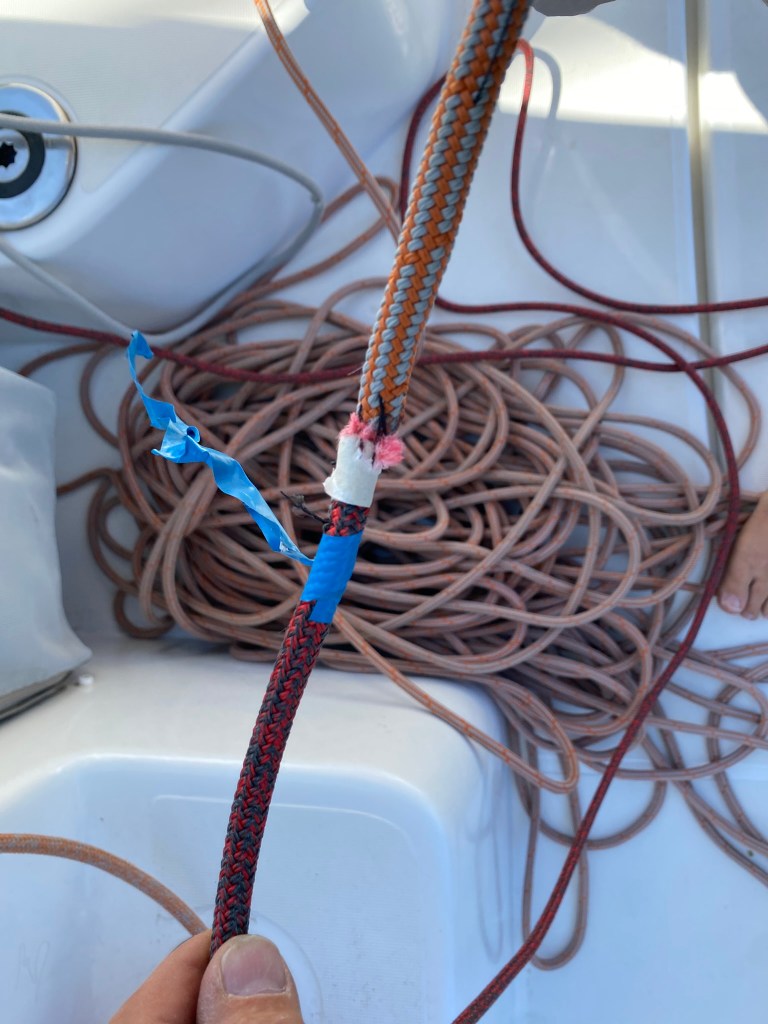

The pulse main sail is a beast. While the stock halyard may be strong enough, the sheath doesn’t hold up as you’re likely pulling the main to the same point for each reef point. This puts a lot of wear on the sheath. For which it has exploded on us, causing quite the problem as we were nowhere near a chandlery that stocks quality lines. The core held, but it was quite a mess at the time and took a bit to realize we can still use the winch to pull and douse. At the time, we used the spinnaker halyard as its just a bit longer to replace the main sail halyard and continue our sail.

To solve this we:

- replaced the main halyard with 10mm Marlow D2 Grand Prix 78, which has a Dyneema core, and 50/50 Technora / Polyester cover to provide even greater performance in clutches, jammer and around winches.

- replaced the cams with Spinlock Ceramic coated cams and base plates.

The other thing to monitor is the 5mm Bunji cords that need to be monitored and replaced.

Dual Downwind Sail Halyards

While we like how well our Code 0 flies in light winds, it is a hassle to raise and douse when you may only want to use it for a short stint. For the 2026 season, we’re reconsidering adding UV protection so we can keep it raised and furled. The problem is we’d still need to douse to raise the gennaker.

Robin Young has been exploring adding a 2nd halyard, and I’m excited to see how he riggs the halyard and tack. He’s mentioned he has space for two spin halyards, although we only appear to have space for one (Hull #10). I have to do some mast-top maintenance, so I’ll have to double check.